Beside mountains of cargo at ports, next to roaring machinery on construction sites, alongside harvested crops in fields, and even within packages of fertilizer or feed ordered online, there is always a seemingly plain yet ubiquitous presence—the polypropylene (PP) woven bag. This unassuming packaging material, with its remarkable toughness and adaptability, quietly supports the vast system of global logistics and trade.

Guardian of “Industrial Grain”

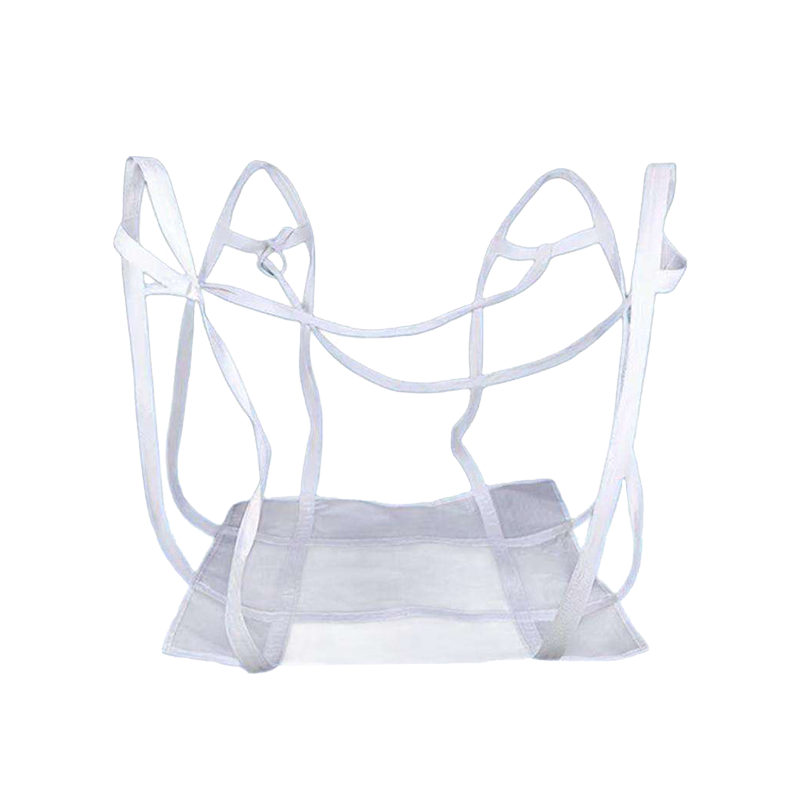

PP woven bags, commonly known as “bulk bags” or “jumbo bags,” are flexible transport packaging made by weaving, sewing, or bonding polypropylene tape yarns. Their core advantage lies in their “high cost-effectiveness.” Compared to traditional packaging like gunny sacks, they are lighter, stronger, more moisture-resistant, and mold-proof. Compared to disposable paper bags or expensive containers, they are low-cost and reusable. This makes them the preferred packaging for bulk materials such as fertilizer, grain, chemical raw materials, and building supplies. It could be said that without the efficient, low-cost sealing and handling provided by PP woven bags, the flow of raw materials and products in modern industry and agriculture would face significant challenges.

“Seventy-Two Transformations” Driven by Innovation

Today’s PP woven bags are far from uniform. Through technological innovation, the industry has endowed them with diverse performances and appearances:

- Functionalization:

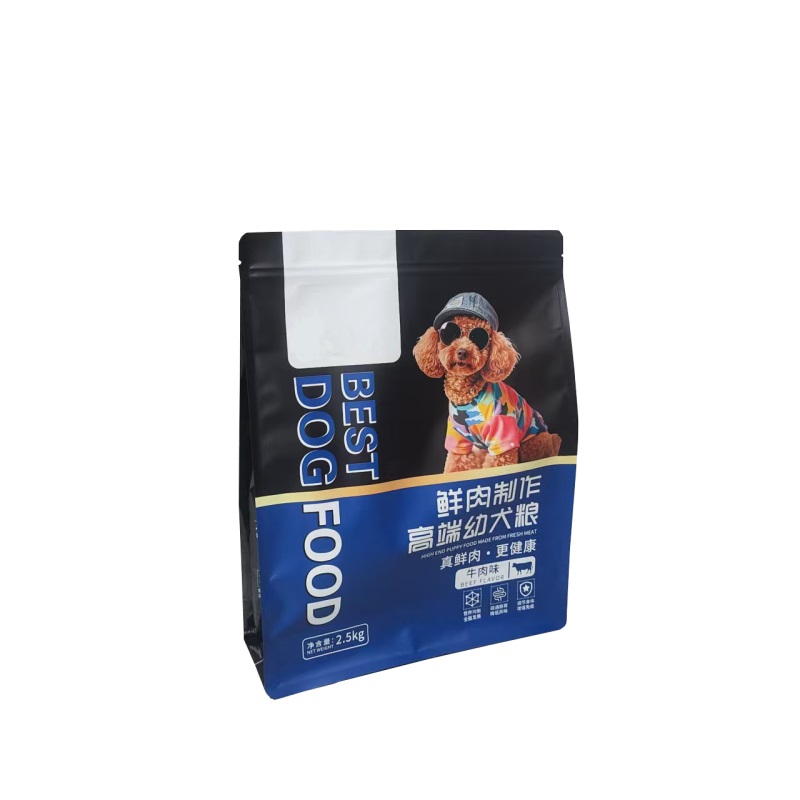

By adding additives or laminating films (such as PE film), properties like moisture-proofing, waterproofing, UV resistance, and anti-static capabilities are achieved, meeting the stringent requirements of special goods in chemical, food, and other industries. - Refinemen:

Improvements in tape yarn weaving technology result in smoother bag surfaces, more uniform grammage, and higher tensile strength. Advances in color printing have turned woven bags into mobile billboards for brands. - Eco-friendliness:Facing sustainability pressures, the industry is actively exploring the use of renewable polypropylene, developing biodegradable materials, and vigorously promoting recycling systems for woven bags. Old bags are regenerated into plastic pellets for manufacturing lower-demand plastic products.

Challenges and the Future: Redefining Resilience Under Pressure

Beneath the industry’s (halo), shadows also exist. The price of raw materials (polypropylene) is closely tied to the international crude oil market, leading to volatile costs. Simultaneously, rising labor costs continually squeeze profit margins in traditional labor-intensive production. The greatest challenge comes from the global trend of “plastic restriction.” Single-use plastic packaging has become a regulatory focus, forcing the PP woven bag industry to accelerate its transition toward a circular economy model—shifting from “produce-use-discard” to “produce-use-recycle-regenerate.”

Looking ahead, the development path for the PP woven bag industry is clear:

Deepen expertise in specific fields (e.g., high-strength FIBCs, food-grade safety bags), using technological barriers to enhance product added value.

Introduce automated equipment and IoT technology to reduce costs, improve efficiency, and achieve precise quality control.

Establish and improve extended producer responsibility systems, building a full industrial chain cycle from recycling to remanufacturing, transforming environmental pressures into new competitiveness.

Conclusion:

The story of the PP woven bag is one about “resilience”—both the physical property of the material itself and the tenacious vitality demonstrated by the entire industry under cost, environmental, and market pressures. It may never become a star in the spotlight, but as a silent yet robust cornerstone of the global supply chain, its continuous self-renewal and adaptation will continue to provide the most basic and reliable support for our world, which depends on efficient connection and transport. Its future hinges on transforming its physical resilience into the sustainable resilience of the industry’s development.